Understanding Water Storage Tanks: Essential Components and Considerations

Introduction and Article Outline: Why Water Storage Matters

Open a tap and water appears—simple on the surface, intricate behind the scenes. Storage tanks, pumps, and pipes work together to balance supply and demand, smooth out pressure swings, and protect quality. In regions with seasonal rains, frequent outages, or variable well yield, a thoughtfully designed storage system becomes a quiet insurance policy. For homeowners, small farms, and facility managers, understanding the essentials of tanks and supply helps prevent costly mistakes and ensures reliable, safe water on ordinary days and during emergencies alike.

This article follows a straightforward plan: first, we map the territory; next, we explore each topic in depth. Think of this as a field guide—part technical compass, part practical checklist—designed to help you make informed decisions without wading through jargon you don’t need.

Outline of what follows:

– Water Storage Tanks: anatomy, materials, placement, accessories, and sanitation

– Water Supply: sources, flow and pressure, pumps, treatment, and protections

– Tank Selection: sizing methods, cost-of-ownership, risk planning, and compliance

– Maintenance and Lifecycle: inspection, cleaning, upgrades, and safety

– Conclusion: action steps tailored to homes, farms, and light commercial sites

Key takeaways to watch for as you read:

– Matching storage to supply is more effective than oversizing blindly

– Materials behave differently under sunlight, temperature, and chemistry

– Small accessories—screens, vents, valves—often decide water quality outcomes

– Sizing should include everyday use, outage reserve, and fire or irrigation needs

– Maintenance planning protects your investment and avoids sudden failures

With the map laid out, let’s walk the terrain—from the tank wall to the tap—so every component pulls its weight and every drop counts.

Water Storage Tanks: Components, Materials, and Placement

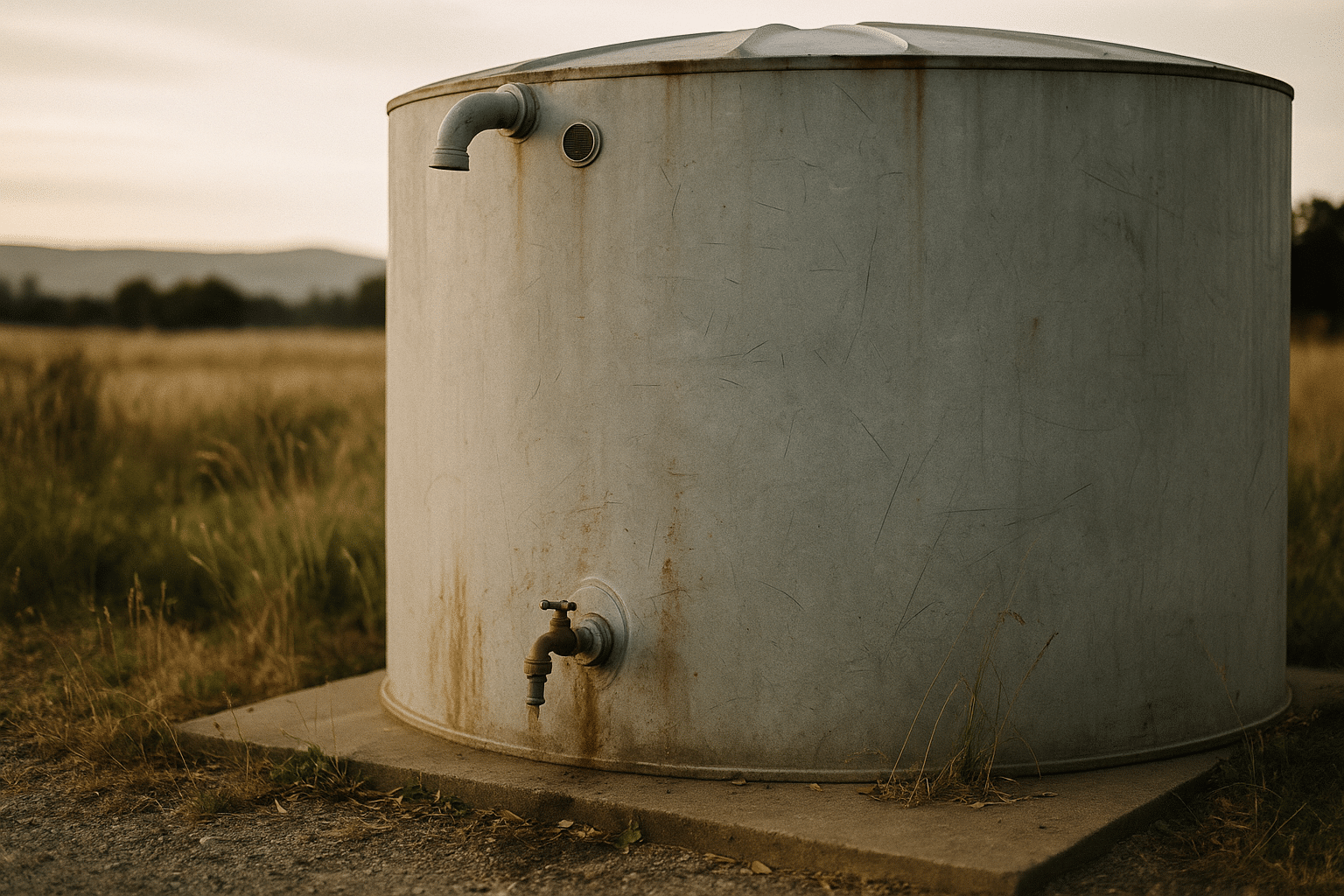

A water storage tank is more than a container; it’s a controlled environment for a vital resource. Its anatomy includes the shell, roof, inlet and outlet penetrations, overflow, drain, vent, level indicators, and access points. Each element affects performance and water quality. A screened vent reduces contamination from insects; a properly directed overflow protects foundations and keeps debris out; an accessible manway enables safe inspection and cleaning.

Common materials and how they compare:

– Polyethylene (rotationally molded): Lightweight, corrosion-proof, and relatively affordable. UV-stabilized variants tolerate sun exposure better, though long-term ultraviolet stress and temperature swings can embrittle unprotected plastics.

– Fiberglass-reinforced plastic: Rigid, chemically resistant, and suitable for above- or below-grade placement; seams and fittings require careful sealing, and external gelcoats benefit from periodic inspection.

– Coated or lined steel: High strength and large capacities with modular panel designs. Protective linings and cathodic strategies are critical to prevent corrosion and safeguard taste.

– Concrete (cast-in-place or precast): Excellent thermal mass, which helps stabilize water temperatures and reduces biological growth; requires water-proofing, joint design, and attention to crack control.

– Modular bladder or pillow tanks: Space-efficient and rapid to deploy; typically used for temporary or remote installations, with protective ground mats and UV shielding.

Placement considerations can be the difference between dependable service and persistent headaches. Elevated tanks provide gravity pressure, while ground-level tanks often need booster pumps and pressure tanks to maintain consistent delivery. Sun exposure increases thermal gain, which can accelerate chlorine decay and promote biofilm; shading, light-colored exterior coatings, or partial burial help. Wind, seismic activity, and frost lines influence foundations and anchoring. Clearances for maintenance matter—leave room to remove a manway cover, replace a valve, or maneuver a cleaning hose.

Essential accessories and why they matter:

– Inlet diffuser: Reduces turbulence, limiting sediment disturbance and stratification

– First-flush diverter (for rain capture): Keeps initial debris-laden runoff out of storage

– Food-grade gaskets and fittings: Protect taste and limit chemical leaching

– Level gauge or sensor: Prevents overflows and dry runs, supports automation

– Screened overflow and vent: Blocks insects and small animals without impeding airflow

Water quality starts with exclusion and control. Keep sunlight out to inhibit algae, ensure all openings are screened, and specify materials rated for potable contact when used for drinking water. Plan for periodic inspections, sediment removal, and safe confined-space practices if entry is required. With these fundamentals in place, a tank becomes a steady partner—quietly balancing supply and protecting every stored liter.

Understanding Water Supply: Sources, Flow, Pressure, and Treatment

Storage and supply are inseparable. How water enters the tank—and at what rate and quality—shapes sizing, pump selection, and treatment steps. Typical sources include municipal mains, drilled wells, and rain capture; in rural contexts, surface water storage may supplement seasonal needs. Each source brings its own pattern of availability, chemistry, and regulatory considerations.

Flow and pressure basics help translate needs into hardware. Household fixtures often draw modest rates—showers around 1.8–2.5 gpm, faucets 1.0–2.0 gpm, and typical irrigation zones 3–8 gpm depending on emitter type. A small home may see peak demands of 8–15 gpm, while a small farm or light commercial site can spike higher during processing or wash-down periods. Municipal pressure commonly ranges from 40–80 psi but can vary widely over the day. Wells deliver according to aquifer yield and pump capacity, sometimes just 1–5 gpm, which makes storage crucial to meet short bursts of higher demand.

Pumps and controls bridge the gap between stored volume and usable pressure. Booster sets paired with pressure tanks limit short-cycling. Variable-speed drives can maintain steady pressure across changing draw, reducing noise and improving energy efficiency. Check valves, isolation valves, and union fittings make service easier; backflow prevention devices protect the upstream supply and are often required by code.

Quality protection is layered. For rainwater used in non-potable applications, leaf screens, first-flush diversion, and fine filtration reduce sediment and organic load. For potable uses, a typical train might include sediment filtration, activated carbon for taste and odor, and disinfection by ultraviolet or chlorine. Source water dictates details: high iron or manganese can stain fixtures; hardness scales heaters and reduces flow; low pH corrodes metals. Testing establishes a baseline so the right media and dosing are chosen. When disinfecting with chlorine, contact time matters—storage geometry and baffles can help ensure adequate exposure before water reaches taps.

Safeguards that often get overlooked:

– Air gaps where practical to prevent backflow

– Screened and elevated inlets to keep splashback contaminants out

– Properly sloped piping to avoid stagnant pockets

– Accessible sample taps upstream and downstream of treatment for verification

– Overflow lines that discharge to visible, sanitary locations

Finally, think about the rhythm of your site. Water use peaks in early mornings and evenings for homes; farms may peak around irrigation or cleaning schedules; small businesses often crest at opening or shift changes. Matching these patterns with measured inflow capacity helps decide whether you need more storage, a different pump strategy, or both.

Tank Selection: Sizing Methods, Risk Planning, and Total Cost

Choosing a tank begins with balancing three needs: everyday consumption, reserve for interruptions, and special events such as firefighting or irrigation surges. A practical sizing method starts with daily demand, adds outage coverage, and then layers any special requirements.

Step-by-step approach:

– Estimate average daily demand: homes often use 50–100 gallons per person per day; farms and light commercial sites should add process needs or livestock allowances.

– Identify peak factors: short bursts may be several times the hourly average; pumps and pressure tanks handle momentary peaks, while storage smooths longer peaks.

– Choose an outage reserve: consider 24–72 hours depending on source reliability, climate, and criticality of operations.

– Add special reserves: irrigation cycles, fire flow (as required by local code), or process water that must not be interrupted.

– Verify refill capacity: ensure the source can replenish storage within the downtime you can accept.

Example calculation for a four-person home with occasional garden irrigation: if indoor use averages 60 gallons per person per day, that’s 240 gallons. Add 2 days of reserve (480 gallons) and an irrigation buffer of, say, 200 gallons for a weekend cycle. A practical target might be 900–1,200 gallons, leaving margin for aging wells or seasonal variability. Where fire reserves are mandated, volumes can jump dramatically, so check local requirements early—designing foundations and piping once is simpler than upgrading later.

Material and geometry choices affect performance and maintenance. Taller, narrower tanks fit tight sites but can stratify; wider, lower tanks may improve mixing. Opaque walls reduce light intrusion; insulated or partially buried tanks temper seasonal swings. For potable storage, select materials certified for drinking-water contact and fittings that resist corrosion from your specific water chemistry.

Total cost of ownership extends beyond the purchase price:

– Installation: foundation, anchoring, trenching, valves, and electrical for pumps

– Treatment: filters, media replacement, disinfection consumables

– Energy: pump efficiency, pressure setpoints, and duty cycles

– Maintenance: periodic inspections, cleaning, repainting or liner replacement

– Risk cost: water damage from overflows, service downtime, or quality incidents

Risk planning ties it all together. If your supply is robust but power is fragile, consider gravity-fed placement or backup power for pumps. In windy or seismic zones, anchoring and flexible couplings prevent ruptures. Where wildlife is prevalent, heavy-duty screens and sealed lids pay for themselves. A well-selected tank, sized with real-world patterns and risks in mind, turns uncertainty into manageable routine.

Maintenance, Safety, and Lifecycle Management

A tank that’s out of sight can drift out of mind, and that’s when small issues become costly. A simple, regular maintenance routine preserves water quality and extends service life. Start with an inspection schedule: monthly visual checks from the exterior for leaks, bulges, paint or coating damage, insect ingress, and loose fasteners; quarterly checks of level sensors, vents, and overflow screens; annual internal inspection where safe and permitted, or at least a sediment assessment and targeted cleaning through drains.

Cleaning practices should fit the material. For polyethylene or fiberglass shells, use soft, non-abrasive brushes and potable-safe cleaners; avoid solvents that can craze or weaken surfaces. Coated steel requires gentle methods that preserve linings, with spot repairs where chips expose metal. Concrete benefits from careful debris removal and attention to joints; any disinfection step should be compatible with the tank’s liner or waterproofing. After cleaning, flush to waste until disinfectant residuals and turbidity stabilize within acceptable ranges.

Safety is non-negotiable. Confined-space protocols apply to many tanks: test air quality, use harnesses and retrieval systems, and ensure trained attendants are present. Lockout/tagout for pumps and mixers prevents accidental activation. Ladders, platforms, and handrails must be sound, and manway covers should be secured to deter unauthorized entry. For buried tanks, be mindful of buoyancy in high groundwater—anchoring and backfill specifications prevent floatation during drawdown.

Over time, even well-kept systems need upgrades. Level sensors drift; gaskets harden; external coatings weather; UV exposure embrittles plastics. Plan for periodic component replacement and set aside a contingency budget. Consider retrofits that improve performance: inlet diffusers, mixing nozzles to limit stratification, or variable-speed drives that stabilize pressure and cut energy costs. If a tank approaches end-of-life, a phased replacement strategy that adds new capacity while the old unit remains in service reduces downtime.

Documentation keeps the system understandable even as personnel change. Maintain a simple logbook or digital record of inspections, repairs, cleaning dates, and test results. Photograph fittings and label valves; keep a schematic that shows pipe sizes, valve locations, and sensor wiring. When everyone shares the same map, troubleshooting becomes faster and safer.

Finally, align your maintenance with local codes and standards for potable contact materials, overflow management, and backflow prevention. Water is persistent—it finds gaps, follows slopes, and carries what it touches. With routine attention to details and a plan that treats the tank as a living part of your water system, you keep that persistence working for you, not against you.

Conclusion: Practical Steps for Homeowners, Farms, and Small Facilities

Reliable water storage is built on matching needs, understanding supply, and choosing materials and accessories that suit the site. For homeowners, that may mean a modest, opaque tank near the utility room, a booster set with a small pressure tank, and simple sediment and carbon filtration for taste. For small farms, it may be multiple tanks plumbed with isolation valves, a mix of gravity-fed irrigation and pressurized domestic supply, and seasonal treatment adjustments as water temperature and turbidity shift. Light commercial sites often prioritize steady pressure, easy service access, and documented maintenance to satisfy inspections and protect operations.

Use this checklist to turn plans into action:

– Measure: log a week of flow events and estimate daily averages and peaks

– Test: analyze source water to tailor filtration and disinfection wisely

– Size: cover daily use, outage reserve, and any fire or irrigation needs

– Place: favor shade or insulation, ensure service clearances, and build a sound foundation

– Protect: specify screened vents and overflows, backflow prevention, and food-grade wetted parts

– Power: consider energy use, backup strategies, and pump control options

– Maintain: set a calendar for inspections, cleaning, and component replacement

Budgets are real, but so are the costs of downtime, water damage, and quality complaints. A balanced approach looks beyond sticker price to the life of the system: energy, consumables, and repairs. Small, thoughtful upgrades—a better vent screen, an inlet diffuser, a level alarm—can prevent large headaches. Just as important, involve local authorities early for any required permits, hydraulic calculations, or firefighting reserves; doing so avoids redesigns and ensures smooth approvals.

Whether you’re installing your first tank or refining a long-standing setup, aim for clarity: know your demand, document your supply, and choose components that work as a team. When each piece supports the next, the result is quiet reliability—the kind you barely notice until a storm knocks out power and your storage carries you through. That’s not luck; it’s good planning, executed with practical care.