A Comprehensive Guide to Careers in a Textile Factory

Introduction: Why Textile Factory Careers Matter + Outline

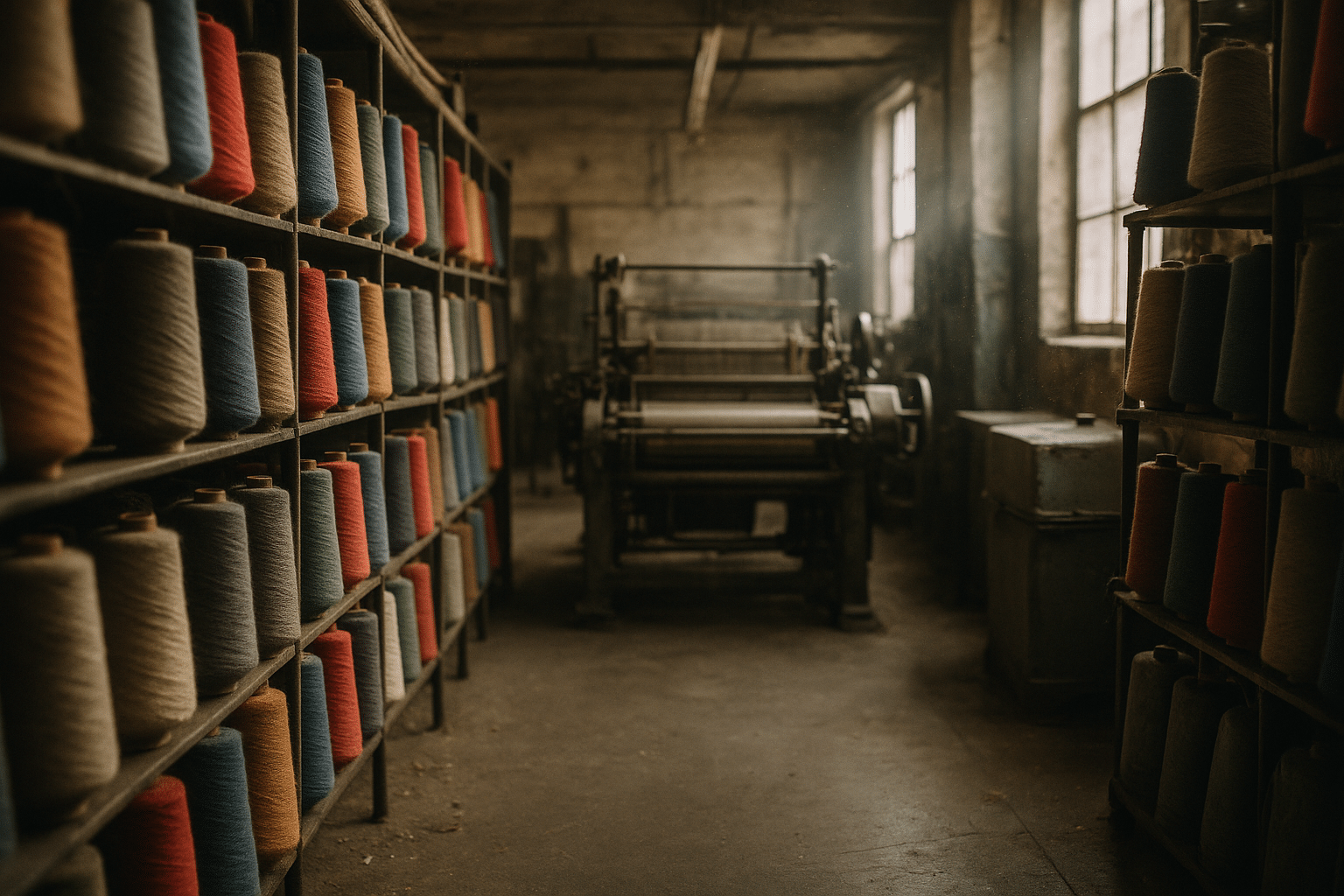

Walk into a textile factory and you’ll hear a steady rhythm of machines, see a tapestry of color moving from raw fiber to finished rolls, and feel the energy of teams keeping production on course. This setting is not only a source of everyday products; it is also a training ground for practical skills, technical mastery, and leadership. From small mills to large integrated plants, textile manufacturing supports livelihoods and regional economies. Industry estimates suggest the textile and apparel value chain employs tens of millions of people worldwide, with strong demand for roles that combine hands-on expertise, safety awareness, and continuous improvement. For job seekers who value tangible results, steady routines, and measurable progress, a textile facility offers a disciplined environment where effort translates into visible outcomes and career mobility.

Textile factories are complex ecosystems. Cotton, wool, synthetics, and new bio-based fibers follow carefully controlled processes—spinning, weaving or knitting, dyeing, finishing, testing, and packing—each led by specialized teams. As automation becomes more accessible and sustainability standards grow more stringent, there is a rising need for technicians who can interpret machine data, reduce waste, and maintain consistent quality. That opens the door for advancement grounded in skill building rather than abstract credentials. Whether you prefer mechanical problem-solving, color science, or supply planning, there is a lane that suits your strengths.

To help you navigate, here is the outline of this guide and what you will get from each part:

– Section 1: Context and relevance of textile careers, plus how the factory ecosystem works.

– Section 2: Core production roles—spinning, weaving/knitting, dyeing and finishing, quality checks, and maintenance on the shop floor.

– Section 3: Technical and support roles—process engineering, labs, quality systems, supply chain, and environmental health and safety.

– Section 4: Career ladders and advancement—promotion paths, cross-functional moves, credentials, and on-the-job learning.

– Section 5: Conclusion and practical next steps—how to enter, grow, and future-proof your textile career.

As you work through the sections, you’ll see realistic descriptions, typical responsibilities, and comparisons that clarify which roles match different working styles. You will also find examples of training routes and productivity measures that supervisors use to evaluate performance. The aim is to give you a grounded picture of the work and the momentum you can build inside this industry.

Key Career Roles: Production and Operations

Production roles are the heartbeat of a textile factory. They demand attention to detail, situational awareness, and a steady tempo—especially on shift-based schedules. A typical path starts with an entry-level operator position and can lead to senior technical responsibilities as proficiency grows. Below are common shop-floor roles and what they involve.

– Fiber preparation operator: Prepares bales, opens, and blends fiber. Success depends on consistent feed rates, moisture control, and correct mix ratios. This role influences downstream quality before a single yarn is spun.

– Spinning operator/technician: Oversees ring, rotor, or air-jet machines; monitors breaks and end-down rates; manages doffing; and maintains yarn uniformity. An eye for patterns in defects—neps, slubs, uneven twist—pays off.

– Weaving or knitting operator: Sets up looms or knitting frames, changes beams, adjusts tension, and tracks faults like broken ends, mispicks, dropped stitches, or barre. Fast response to alarms prevents rework.

– Dyeing and finishing operator: Loads jets or continuous ranges, controls temperature, pH, liquor ratios, and dwell times; manages softeners, resins, and mechanical finishing steps. Small deviations can create shade variation or hand-feel changes.

– Quality control inspector: Checks greige and finished fabric for defects using standardized grading; verifies shade consistency under controlled light; records data for traceability and feedback to production.

– Maintenance fitter/electrician: Keeps equipment reliable through preventative checks—belts, bearings, pneumatics, valves—and responds to breakdowns. Quick diagnostics limit downtime and avoid scrap.

Daily success is measured through indicators such as efficiency, first-pass yield, waste percentage, machine uptime, and complaint rates. For example, a weaving team might track picks per minute and warp break frequency, while dyeing operators monitor shade delta and lab-to-bulk reproducibility. Safety metrics matter equally: guarding, lockout procedures, correct handling of chemicals, and proper ergonomics. Operators who document issues, communicate clearly at shift handover, and suggest improvements often move quickly into senior roles.

Comparing these roles reveals different working rhythms. Spinning and weaving require constant vigilance and rapid troubleshooting across multiple machines; dyeing and finishing involve longer cycle times with critical control points; inspection requires patience and visual acuity; maintenance demands methodical analysis under time pressure. If you enjoy fast problem-solving and light mechanics, a loom or knitting station might suit you. If you prefer controlled processes and chemistry, dyeing is a strong fit. If you like instruments and checklists, inspection and testing align well. Each role is vital, and cross-training among them increases both employability and resilience when shifts change or lines expand.

Key Career Roles: Technical, Quality, Supply Chain, and Support

Beyond the core machines, a textile factory relies on technical, quality, and logistical roles that keep standards high and materials moving. These positions often blend desk analysis with shop-floor presence, making them appealing to people who enjoy both data and practical work.

– Process or industrial engineer: Maps workflows, balances lines, sets standard times, and designs experiments to cut defects or energy use. They create work instructions, optimize changeovers, and validate improvements with statistical tools.

– Laboratory technician/colour specialist: Mixes recipes, manages dye libraries, performs wash and rub tests, and checks fastness. Precision in lab-to-bulk scale-up can prevent costly re-dyeing and delivery delays.

– Quality assurance lead: Maintains procedures, audits processes, investigates nonconformities, and drives corrective actions. They coach inspectors and operators on standard methods and measurement discipline.

– Environmental health and safety coordinator: Oversees chemical inventories, wastewater parameters, air and noise limits, and incident reporting. They train teams on personal protective equipment and emergency response.

– Maintenance planner/automation technician: Builds preventive schedules, manages spares, and tunes sensors, drives, and control logic. Integrating condition monitoring reduces unplanned stoppages.

– Production planner: Converts orders into schedules, allocates beams and dye lots, monitors work-in-process, and resolves bottlenecks. They work closely with supervisors to align capacity with demand.

– Procurement and logistics specialist: Sources fibers, chemicals, and packaging; negotiates lead times; books transport; and maintains traceability. Accurate documentation supports compliance and customer trust.

– Training and people development coordinator: Curates skill matrices, runs onboarding, organizes refresher sessions, and tracks certifications across shifts.

These roles interact constantly. A lab technician collaborates with dyeing operators to correct shade; a quality lead and process engineer pair up to reduce recurring faults; a planner adjusts the sequence to avoid excessive loom changes; maintenance schedules critical work during planned downtime. When a new fabric line starts, this cross-functional team designs the ramp-up plan, defines quality gates, and standardizes the first successful run. The best outcomes come from visibility: clear dashboards, concise daily meetings, and a habit of closing the loop on issues.

Choosing among these positions depends on your interests. If you enjoy experiments and structured problem-solving, engineering offers variety and measurable wins. If you love color and accuracy, the lab gives space for careful method. If coordination is your strength, planning and logistics deliver constant puzzles to solve. Many professionals cycle through two or three of these paths over a career, building a well-rounded profile that prepares them for supervisory or department leadership roles.

Career Path and Advancement Opportunities

Advancement in textile factories rewards skill growth, reliability, and teamwork. Most plants outline clear ladders with practical milestones and mentoring. While titles vary by region, the progression typically follows a consistent pattern, and lateral moves often accelerate learning.

– Operator track: Operator → Senior Operator → Line Leader → Shift Supervisor → Production Manager. Progress hinges on mastering machine setups, stabilizing quality, guiding handovers, and coaching new hires. Demonstrating control over waste reduction and uptime is a common requirement.

– Technical track: Technician → Senior Technician → Specialist (e.g., warp room, automation, color) → Department Technologist → Technical Manager. Documented problem-solving, standardization of successful settings, and contributions to training materials signal readiness for the next step.

– Quality and lab track: Inspector → Auditor → QA Lead → Quality Manager. Improvements in complaint resolution time, fewer customer returns, and strong audit results are typical markers.

– Engineering track: Junior Engineer → Process Engineer → Senior Engineer → Continuous Improvement Lead → Operations Excellence Leader. Success is tied to sustained gains in throughput, changeover time, and resource efficiency.

– Supply chain track: Planner → Senior Planner → Scheduling Lead → Supply Chain Manager. Reliable delivery performance, stable inventory turns, and smooth cross-shift coordination matter most.

Enablers for promotion include communication, consistency, and evidence. Keep a simple portfolio: before-and-after photos of defects, charts of cycle-time reductions, summaries of training you delivered, and safety improvements you initiated. Many factories support short courses in areas such as quality auditing, statistical process control, chemical handling, and machine maintenance basics. Cross-training is a powerful lever: weaving operators who learn dyeing fundamentals make more informed decisions during fabric trials; lab technicians who shadow maintenance understand hardware limits and reduce rework. Supervisors notice people who learn beyond their station and share that knowledge.

Compensation and schedules generally track responsibility. Supervisory roles may come with added shift coordination, performance meetings, and customer calls; technical leadership roles may focus on project deadlines and audits. Across paths, steady attendance, clean documentation, and calm responses during breakdowns build trust—the currency of advancement. If you’re early in your journey, aim for one tangible improvement per month, however small, and document it. Over a year, that portfolio tells a compelling story of growth.

Conclusion: Your Next Steps in Textile Careers

Textile manufacturing offers a spectrum of roles for different personalities: hands-on operators, methodical inspectors, curious lab specialists, system thinkers in engineering, and organizers in planning and logistics. The work is real, the impact is visible, and the progression is attainable with practice and patience. To move from interest to action, start by matching your preferences to the rhythms of each role, then stack targeted skills that make you indispensable to a team.

Here is a practical way to begin:

– Visit a local mill or training center to observe machines and workflows; note the pace and communication style on the floor.

– Build fundamentals: measurement units, basic fiber properties, common defects, and simple maintenance checks.

– Earn entry-level certificates where available: chemical safety, machine guarding, first aid, and internal quality auditing.

– Keep a learning log from day one: settings you tried, outcomes you saw, and questions to ask a senior colleague.

– Volunteer for cross-training days; shadow an adjacent department and summarize what you learned for your team.

As factories adopt more automation and deepen sustainability efforts—water recycling, energy metering, and traceable inputs—demand will rise for professionals who can bridge shop-floor know-how with data literacy. That means comfort with dashboards, trend charts, and root-cause discussions will serve you well, even if your primary role remains hands-on. The most resilient careers blend reliability with curiosity: you do your job consistently, and you actively look for the next small improvement. If you carry that mindset into any textile facility, you’ll find pathways to grow—sometimes upward into leadership, sometimes sideways into a specialty, and often both over time. Your first step could be as simple as touring a plant, asking good questions, and picturing where you would thrive in the hum of the machines.