How to Choose Reliable Floor Installers

Outline:

1) Define reliability in floor installation—meaning, measurable indicators, and why it affects cost and longevity.

2) Credentials, insurance, and compliance—licenses, coverage, and safety practices that protect you.

3) Proof of workmanship—portfolios, references, and site visits that reveal real skill.

4) Scopes, pricing, and documentation—clarity that reduces risk and prevents scope creep.

5) Decision framework—shortlist method and practical next steps.

Defining Reliability in Floor Installation: What It Means and Why It Matters

Floors are the stage every room performs on, and reliability is the unseen stagehand making sure the show goes on—quietly, safely, and on schedule. In practical terms, reliability means consistent delivery against specifications, timeframes, and budgets with minimal callbacks. For homeowners and facilities managers, this translates into fewer disruptions, longer surface life, and lower total cost of ownership. A reliable installer doesn’t just lay planks or tile; they manage moisture, subfloor flatness, transitions, and finishes in a way that safeguards the manufacturer’s warranty and your peace of mind.

To define reliability, convert vague assurances into measurable indicators. Useful metrics include: on-time completion rate above 90%; a callback rate under 3–5% in the first 12 months; and documented compliance with product tolerances. Subfloor flatness is a common make-or-break detail—typical tolerances are around 3/16 inch over 10 feet for many floating planks, 1/8 inch over 6 feet for glue-down hardwood, and tighter ranges for large-format tile. Moisture control is equally critical: solid or engineered wood often performs best when the wood moisture content sits roughly in the 6–9% range and within about 2–4% of the subfloor, while adhesive manufacturers may specify concrete relative humidity thresholds in the 75–85% range. Reliable installers can show you prep logs, moisture readings, and acclimation notes that align with the product data sheet.

Reliability also shows up in process design. Expect a pre-install walkthrough to identify risks (high moisture, uneven slabs, HVAC not operational), a written plan for dust control, and clear communication about areas of responsibility (furniture moving, toilets, baseboards). The payoff is tangible: a properly flattened subfloor reduces hollow sounds, eliminates telegraphing, and results in tighter joints that resist seasonal movement. The cost of prevention is almost always lower than the cost of rework. A short case example: skipping slab moisture testing can lead to cupping or adhesive failure within weeks; a $150 moisture test could avert a multi-thousand-dollar tear-out.

Watch for these signals:

– Documented assessments: moisture, flatness, and acclimation logs.

– Transparent scheduling with buffers for cure times.

– Product-specific installation methods tied to the manufacturer’s instructions.

– Minimal punch list items and a structured closeout process.

Credentials, Insurance, and Compliance Checks That Protect You

Credentials are your first line of defense. In most jurisdictions, flooring contractors require a license or registration—verification takes minutes through a state or local database and reveals status, classifications, and any disciplinary actions. Beyond licensing, look for evidence of structured training, such as installer certifications or documented coursework in substrate prep, moisture mitigation, and safety. While titles and certificates alone don’t guarantee quality, they signal a commitment to recognized standards and continuing education.

Insurance coverage protects both parties when the unexpected happens. At minimum, request general liability (often $1–2 million aggregate), workers’ compensation for any employees or laborers, and evidence of commercial auto coverage if vehicles will be on-site. Ask for a certificate of insurance naming you (or your building/association) as certificate holder so you are notified of policy changes. Bonding may be required for public or larger private projects; even when not mandated, a bond adds another layer of financial assurance that work will be completed per contract terms.

Compliance obligations keep jobsites safer and warranties intact. For homes built before 1978, lead-safe practices may be mandatory. On all projects, safety training helps reduce risk—items like hazard communication, fall protection where needed, and silica dust controls during cutting or grinding. If permits are required for subfloor replacement or structural adjustments, verify they’re pulled under the contractor’s name. Reliable crews also standardize housekeeping: cord management, clean cuts, HEPA-filtered vacuuming, and daily debris removal signal discipline and reduce trip hazards.

What to verify and how:

– License/registration number and expiration date; cross-check online.

– Certificate of insurance delivered directly by the insurer, not just a photocopy.

– Written safety plan for dust, noise, and access control (especially in multifamily settings).

– Compliance with building or community rules: work hours, elevator protection, staging areas.

– A documented warranty policy describing workmanship coverage and claim steps.

Red flags include reluctance to share insurance documents, vague license details, and evasive answers about safety or warranty procedures. Well-regarded professionals volunteer this information early because it sets expectations and protects everyone involved.

Proof of Workmanship: Portfolios, References, and Site Visits

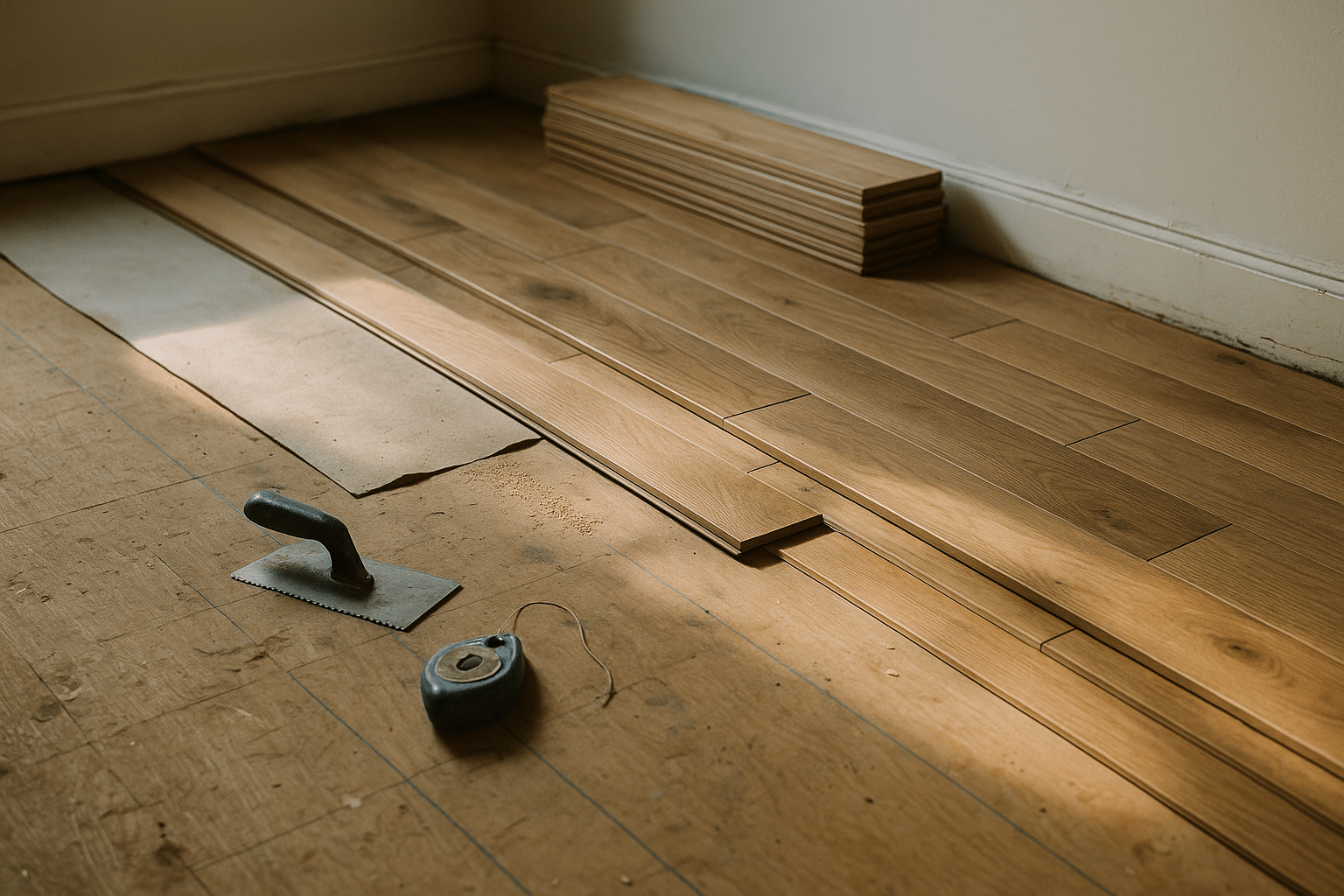

Proof beats promises. Portfolios should move beyond glamour shots and include process photos: subfloor grinding or patching, moisture readings, layout lines snapped on the floor, and detail shots of stair nosings, transitions, and terminations at doorways. Ask for projects comparable to yours—if you have a herringbone hardwood pattern, request herringbone examples; if you need large-format tile, look for rooms where lippage control and movement joints are visible. Good portfolios annotate challenges and solutions: “high slab RH mitigated with approved primer and sealer,” or “radiant floor accommodated with temperature staging.”

References reveal how crews perform when plans meet reality. Call at least three: two recent clients and one from 12–24 months ago to gauge durability and support after the check clears. Questions to ask:

– Did the crew start and finish on the agreed days?

– How were change orders handled—fair pricing and clear documentation?

– Was dust contained and daily cleanup consistent?

– Were there callbacks? If yes, what was the response time and resolution?

– Would you hire them again, and would you change anything next time?

Site visits turn intuition into evidence. If possible, visit an active job for 10–15 minutes. Observe the subfloor prep: are they checking flatness with a straightedge and addressing low or high spots? Watch layout: are reference lines visible, and do they dry-fit starter rows to confirm widths at the far wall? Look for crisp scribe cuts at irregular walls, undercut door jambs where appropriate, and balanced planks at corridors to avoid slivers. For wood floors, check for expansion gaps at perimeters and around fixed objects; for adhered products, glance at trowel size and coverage—industry guidance often targets high coverage rates in traffic areas. Transitions should be secure, level, and color-matched; stair nosings aligned and firmly fastened.

Quality tells on the edges and in the light. Stand at a doorway and let natural light rake across the surface; misalignments and unevenness become obvious. Reliable installers encourage this scrutiny because they know their process can handle the spotlight.

Scope, Pricing, and Documentation: Turning Estimates into Predictable Outcomes

Clear paperwork creates predictable projects. Start by requesting apples-to-apples proposals that itemize labor and materials. A complete scope typically calls out demolition and disposal, subfloor prep (flattening, patching, moisture mitigation), underlayment selection, product quantities and overage, trims and transitions, stair details, baseboards or shoe molding, furniture moving, protection of adjacent finishes, and post-install cleanup. Line items prevent scope creep and help you understand differences between bids—one price might be lower simply because it omits moisture treatment or floor leveling.

Schedule transparency is equally important. A practical timeline identifies mobilization, prep days, material acclimation (as needed), installation phases, cure times before moving furniture or rugs, and final walkthrough. Pair the schedule with a payment plan aligned to milestones—modest deposit, progress payments upon measurable achievements (e.g., subfloor prep complete), and a small retainage until the punch list is closed. Warranties should specify coverage length, what’s included, exclusions, and how to file a claim. Quotes, contracts, schedules, and warranties that prevent surprises.

Define how changes will be handled. A change order policy should state who can authorize changes, how pricing is calculated, and how the schedule will be adjusted. Include allowance amounts for uncertain items (e.g., unforeseen subfloor damage) so you can compare contractors on the same basis. Ask each bidder to state what they have excluded; exclusions are where misunderstandings hide.

Practical checklist to align proposals:

– Request a standard bid form to normalize line items across contractors.

– Ask for a written schedule with start/finish dates and cure-time notes.

– Require documented moisture testing and subfloor flatness tolerances.

– Confirm warranty terms for workmanship and how they interact with product warranties.

– Agree on communication cadence: daily text updates or end-of-day summaries.

With this structure, you’re comparing not just prices, but the likelihood of a smooth, compliant installation that performs over time.

From Longlist to Signed Contract: A Shortlist Method and Next Steps

Decision time becomes easier when you treat it like a small project. Build a longlist of six to eight installers from local recommendations and verified directories, then narrow it using documented criteria. Score each on reliability signals (process logs, portfolio relevance, references), credential strength (licenses, insurance, safety practices), communication quality, schedule feasibility, and price realism. Weighting example: reliability and process 40%, price 25%, schedule 20%, communication 15%. This isn’t rigid—adjust for your priorities—but weighting helps avoid overvaluing a low bid that omits critical prep.

Conclusion with a shortlist method and next steps.

Practical steps to move from research to action:

– Step 1: Send a standard bid template to three or four finalists so you can compare line items directly.

– Step 2: Conduct brief video or in-person walkthroughs to confirm measurements, subfloor risks, and logistics (parking, elevators, pets).

– Step 3: Verify two recent references and one older job; if possible, do a quick site visit.

– Step 4: Request a written schedule with milestone-based payments and retainage for the punch list.

– Step 5: Confirm warranty terms in writing and how warranty service calls are scheduled.

– Step 6: Choose a finalist, sign the contract, and set a pre-install checklist for material delivery, acclimation, and room prep.

Next, prepare the space to set your installer up for success: stabilize indoor climate to product specs, clear rooms, protect adjacent areas, and confirm where materials will be staged. Share any must-meet dates early (move-in, events) and ask for contingency options if something slips. After the final walkthrough, keep copies of moisture readings, prep notes, leftover planks or tiles for future repairs, and care instructions. A thoughtful finish today means fewer surprises tomorrow and a floor that supports daily life—quietly and reliably—for years.