Protecting Your Home from Common Winter Freezes

Outline:

– Understanding the physics of freezes, where homes fail, and the costs of inaction

– Insulating Pipes and Plumbing: materials, methods, locations, and common mistakes

– Protecting Your Roof from Ice Dams through air sealing, insulation, and ventilation

– Monitoring, maintenance, and emergency response when temperatures plunge

– Conclusion: Preparing for Winter with a practical checklist and timelines

Understanding the Risks of Winter Freezes

On a still, bright night when the thermometer drops, your home becomes a lesson in physics. Water expands by roughly nine percent when it freezes, and that expansion can raise pressure inside a pipe to the point where the metal or plastic fails at its thinnest or most stressed spot. In practice, many burst pipes occur not during the coldest moment, but when temperatures rebound and thawing water rushes through a pipe weakened by ice. Risk rises dramatically when outdoor temperatures stay near 20°F (-6°C) or lower for several hours, especially where plumbing runs through unheated spaces like crawl spaces, exterior walls, garages, and attics.

Wind chill doesn’t cool inanimate objects below the air temperature, but moving air accelerates heat loss, nudging marginal pipes closer to freezing. Indoor behaviors matter as well: deep thermostat setbacks overnight, closed interior doors that isolate warm air from plumbing, or shutting off heat during an absence can all tip the balance. Homes in milder regions face unique exposure because plumbing may be routed through attics or poorly insulated cavities, leaving systems vulnerable during rare cold snaps. Power outages, which often coincide with winter storms, remove heating at the very moment protection is most needed.

Watch for early signs: slow or uneven flow at faucets, frost on exposed runs, and unusual odors from drains that can signal partially frozen vents or traps. Simple staging reduces exposure before the coldest hours arrive. Consider the following risk checkpoints to prioritize action:

– Exposed pipes in basements, crawl spaces, and garages without heat

– Plumbing in exterior walls, especially behind cabinets and showers on north-facing sides

– Outdoor hose bibs and irrigation lines that may still hold water

– Attics with ductwork or water lines, typical in some warm-climate builds

– Long, uninsulated pipe runs that pass through vents or gaps with noticeable drafts

Understanding these dynamics transforms reactive repairs into preventive strategy. By identifying where heat is lost, where water sits, and how air moves, you can choose targeted measures that are more effective than broad, costly fixes done after damage occurs.

Insulating Pipes and Plumbing

Insulation is a cost-effective first line of defense. The goal is to slow heat loss enough to keep water above freezing, not to make pipes warm. Start by mapping every run you can access—basements, crawl spaces, utility rooms, attics, garage ceilings, and under sinks. Fit closed-cell foam sleeves snugly along straight sections, using thicker wall foam where space allows; seal all seams and joints with compatible tape to prevent gaps. Around elbows and valves, use preformed pieces or carefully cut and tape foam to maintain continuous coverage. For irregular areas or higher temperatures (like near water heaters), fiberglass wrap with a vapor-retarding jacket can be useful, provided it’s kept dry.

Materials vary in flexibility, R-value, and moisture resistance. Polyethylene foam is widely available and easy to install; elastomeric rubber handles tighter bends and resists condensation; fiberglass with foil or plastic facing offers higher temperature tolerance around boilers and flues (observe clearances). Thicker insulation generally improves performance, but the fit must be complete—small openings near hangers or tees often become freezing points. Air sealing the surrounding cavity can be just as important: foam around pipe penetrations, sill plates, and rim joists to cut wind washing that strips heat away from insulated pipes.

When conditions are severe or history shows repeated freezing, consider UL‑listed heat cable installed per manufacturer guidance and local code. These self-regulating systems adjust output with temperature, but they must be sized correctly, never overlapped, and powered from protected circuits. Use them as a complement to, not a substitute for, insulation and air sealing. Inside the home, small operational tweaks help: open vanity doors on exterior walls to share room heat, keep interior doors ajar to circulate air, and let a distant cold-water tap drip during extreme cold to maintain movement and reduce pressure buildup.

Don’t overlook outdoor components. Remove hoses, install insulated faucet covers, and shut interior isolation valves leading to exterior spigots; then open the outside faucets to drain residual water. Irrigation systems should be winterized according to local climate—manual draining, compressed-air blowout by a licensed professional, or automatic drain valves where appropriate. A quick cost-benefit summary can guide action:

– Low cost: foam sleeves, tape, faucet covers, cabinet doors open, strategic dripping

– Moderate cost: air sealing with cans of foam and weatherstripping, thicker insulation, valve relocations

– Higher cost: rerouting pipes away from exterior walls, adding heat cable with dedicated circuits, insulating and air sealing entire crawl spaces

Investing in the right combination creates a layered defense that performs during both routine cold and the occasional arctic plunge.

Protecting Your Roof from Ice Dams

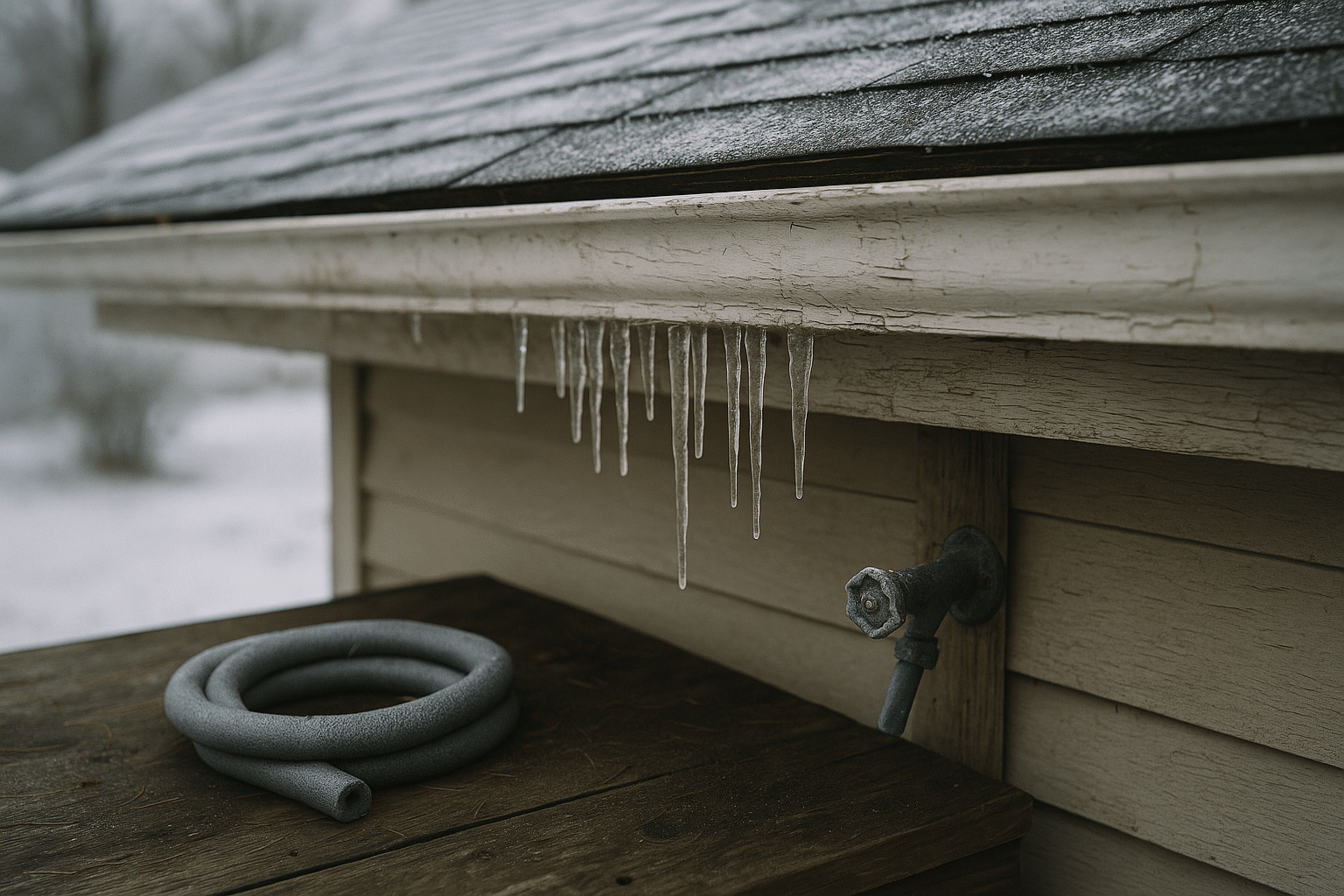

Ice dams form when heat escapes into the attic, warming the roof deck enough to melt snow, which then refreezes at the colder eaves and gutters. As the ridge melts and the edge refreezes, a ridge of ice traps water that can back up under shingles, wetting sheathing, staining ceilings, and compressing insulation. The core fix is not on the roof surface but below it: stop indoor heat and moisture from reaching the attic, insulate to recommended levels, and ventilate so the roof remains uniformly cold. This trio—air sealing, insulation, and ventilation—works together and is more dependable than any one measure alone.

Begin with air sealing the attic plane. Caulk or foam gaps at top plates, wire and pipe penetrations, plumbing vents, and around recessed lighting rated for insulation contact. Weatherstrip and insulate the attic hatch. Once leakage is contained, bring insulation up to local code or energy‑program guidance; in many cold regions, that means roughly R‑49 to R‑60, installed evenly without compressing batts or blocking airflow. Ventilation completes the system: continuous soffit intake paired with ridge exhaust helps move cold, dry air through the rafter bays. Baffles (rafter vents) keep insulation from spilling into soffits and preserve a clear channel for airflow.

Surface tactics still matter. Rake snow from the first 3–4 feet of roof at the eaves with a long-handled rake from the ground after storms to lower meltwater load. Keep gutters clear of leaves so meltwater can drain freely—gutters don’t cause ice dams by themselves, but clogged troughs can worsen refreezing at the edge. Electrically heated de-icing cables can create pathways for meltwater in stubborn locations, yet they are most effective when combined with the underlying attic improvements above. Pair these steps with Maintaining Your Heating System so indoor temperatures remain stable and humidity controlled, helping the attic stay cooler and drier.

Prioritize effort by timeframe:

– Immediate: safely rake eaves, clear downspouts, and manage indoor humidity to 30–40% during cold snaps

– Near-term: air seal penetrations, add attic hatch insulation, install baffles at all eaves

– Seasonal: bring insulation to target R-values and verify continuous soffit and ridge ventilation

– Ongoing: monitor for icicles at the eaves and uneven roof melt patterns that signal warm spots

With the right sequence, you reduce the conditions that create ice dams rather than chasing their symptoms after damage appears.

Monitoring, Maintenance, and Emergency Readiness

Preparation pays off when temperatures plunge overnight or a storm knocks out power. Think in layers: monitoring, routine maintenance, and a calm response plan. Place inexpensive thermometers or smart sensors near known cold spots—behind kitchen sinks on exterior walls, in crawl spaces, near garage ceilings, and in unheated mechanical rooms. Leak detectors on floors near water heaters, washing machines, and under sinks provide early alerts if a line thaws and fails. Label the main water shutoff and tool up accordingly so any adult in the household can act without hesitation.

Routine maintenance underpins resilience. Drain and service sediment from water heaters, inspect visible piping for corrosion or abrasion at hangers, and test sump pumps before the season turns. Seal recurring drafts at rim joists and sill plates, and verify weatherstripping on exterior doors. If you travel, set the thermostat to no lower than the mid‑50s Fahrenheit, ask a neighbor to check the property, and use timers to cycle interior air. Keep interior doors open to balance temperatures, and move space-heating appliances away from pipe runs to avoid uneven hot‑cold zones that promote condensation and freezing elsewhere.

When a pipe freezes, act methodically:

– Open the nearest faucet to relieve pressure and encourage flow

– Warm the frozen section slowly with a hair dryer or portable heater positioned safely, never an open flame

– Start heating near the faucet end and work back toward the freeze to prevent steam from becoming trapped

– If you cannot locate the freeze, or if thawing is slow, shut the water at the main to avoid a sudden burst during thaw

If a line ruptures, shut off the main immediately, open both high and low faucets to drain system pressure, and begin controlled cleanup: move valuables, contain water with towels and a wet vacuum, and ventilate. Drying within 24–48 hours helps minimize secondary damage. Document conditions for your insurer with photos, and schedule a licensed professional to assess structural and electrical impacts if water traveled through walls or ceilings.

An emergency kit reduces stress: a bright flashlight, spare batteries, valve wrench, thermometers, heavy towels, mops, plastic sheeting, and a compact fan. Keep numbers for local utilities and qualified trades in one place. With monitoring in place, maintenance up to date, and a clear response plan, most freeze events become manageable inconveniences rather than full-blown crises.

Conclusion: Preparing for Winter

Winter readiness is less about heroics and more about steady, methodical steps that add up. Start with a walkthrough to spot vulnerabilities, then address them by priority and budget. In a weekend, you can insulate exposed pipes, air seal obvious gaps, clean gutters, and label the main water shutoff. Over a month, you can bring attic insulation to target levels, improve ventilation, and relocate problem pipes from exterior walls. The payoff shows up in fewer emergencies, a quieter home, and lower energy use whenever the mercury dips.

Use this simple plan to organize the season:

– Today: map vulnerable pipes, buy foam sleeves and tape, remove hoses, add faucet covers

– This week: seal attic penetrations, insulate the hatch, add baffles, and clear gutters and downspouts

– This month: upgrade attic insulation, verify soffit-to-ridge ventilation, and consider heat cable for persistent cold corners

– Before travel: set heat to mid‑50s or higher, open cabinet doors on exterior walls, and place leak sensors by high-risk fixtures

Keep documentation of what you’ve done—photos of insulated lines, notes on shutoff locations, and dates for filter changes and roof inspections. A small logbook helps you maintain momentum year to year and simplifies conversations with contractors when you need specialized work. If you’re coordinating on a budget, tackle the highest risk at the lowest cost first: foam and air sealing usually offer an immediate return, while insulation and ventilation upgrades follow as resources allow.

Most importantly, stay observant after the first cold snap. Look for icicles that cluster at specific eaves, taps that slow unexpectedly, and rooms that feel notably cooler; these small clues point to larger patterns you can fix before damage sets in. With a practical checklist, a few affordable materials, and a clear sequence, you’ll move into the cold season with confidence—house protected, systems tuned, and surprises kept to a minimum.