Fast-Track Your Career: Enroll in the 6 Months HVAC Technician Course for In-Demand Skills in 2025

Article Outline and Why HVAC Skills Matter in 2025

Heating, ventilation, air conditioning, and refrigeration are the quiet engines of modern life. From keeping vaccines at safe temperatures to regulating indoor comfort during heat waves, these systems are essential infrastructure. In 2025, several forces converge to elevate the value of job-ready technicians: aging equipment in buildings, momentum toward high-efficiency systems, growing attention to indoor air quality, and the rise of smart controls that require both technical and diagnostic skill. In many regions, heating and cooling represent a substantial share of building energy use, and improving performance delivers measurable savings and comfort gains. That puts practical, evidence-based training front and center for people entering or reskilling into the trades.

This guide opens with a concise outline so you can see how the parts fit together before diving in. You will find a focused look at three foundational topics taught in technician programs, a clear six-month curriculum map that blends classroom learning with hands-on labs, and an in-depth review of job opportunities immediately after graduation and over the long term. Whether you prefer residential service calls or large commercial projects, the path typically begins with the same core competencies and safety practices.

Here is the roadmap for the article you are about to read:

– Three Key Topics Covered in the Course: refrigeration fundamentals; electrical and controls; air distribution, load calculations, and safety.

– Six-Month HVAC Technician Course: what you learn each month, expected time commitments, and typical lab work.

– Job Opportunities After Completing the Course: entry-level titles, typical responsibilities, growth sectors, and advancement ladders.

– Tips sprinkled throughout: study habits, tool familiarity, and how to translate lab experience to the field.

– A closing summary with an action checklist to help you decide if now is the right moment to enroll.

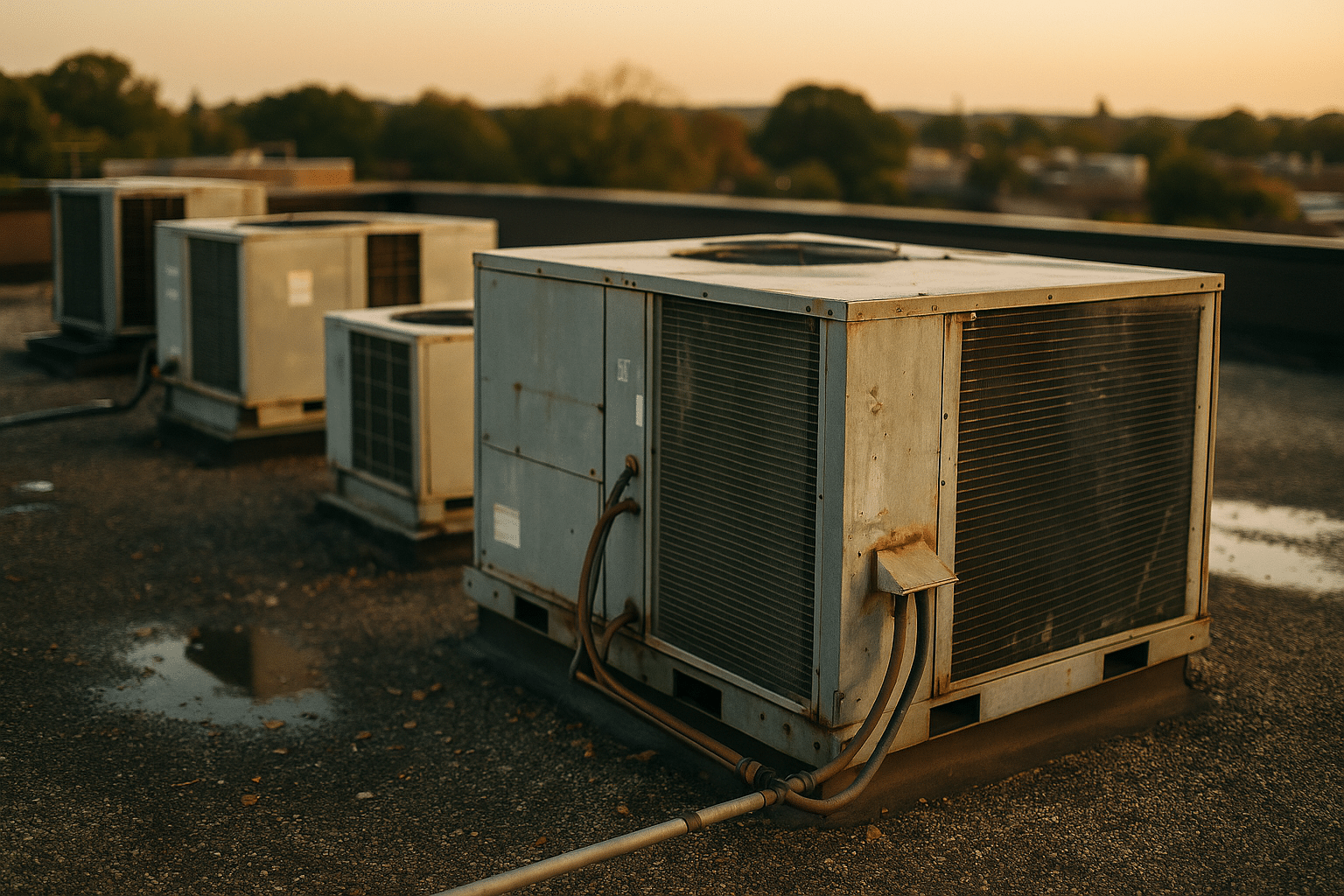

Think of this piece as a practical field manual in narrative form. It favors clarity over jargon while still respecting the technical depth that makes the trade rewarding. As you read, imagine the hum of a rooftop unit at sunrise, the precision of a manifold gauge set, and the satisfaction of diagnosing a tricky intermittent fault. If that vision appeals to you, a concentrated six-month program can be a strong first step toward dependable work and steady advancement.

3 Key Topics Covered in the Course

Refrigeration Fundamentals and the Vapor-Compression Cycle: At the heart of cooling is a simple yet powerful concept—move heat from where you do not want it to where it can be released. You will trace refrigerant through the compressor, condenser, metering device, and evaporator, learning how pressure and temperature are linked. In lab, you practice pulling a deep vacuum, weighing in refrigerant accurately, and reading superheat and subcooling to confirm charge and airflow. Expect to compare legacy refrigerants with lower global-warming-potential alternatives and to discuss safe handling, leak prevention, and recovery procedures. Practical exercises often include building a small sealed system on a trainer board and intentionally introducing faults to learn systematic troubleshooting.

Electrical and Controls for Reliable Operation: Many service calls are electrical in nature, so you will become comfortable with meters, diagrams, and protective devices. The curriculum typically covers AC/DC basics, series and parallel circuits, contactors, relays, capacitors, motors, sensors, and basic control logic. You will interpret wiring schematics and trace signal flow from thermostat to compressor and fans. A key comparison you will explore is analog versus digital control: relays and simple thermostats offer straightforward operation, while modern controllers integrate sensors and timed sequences for efficiency and comfort. Labs frequently include safe live testing, motor capacitor diagnosis, and building simple control circuits. You will also learn lockout/tagout, arc-flash awareness, and how to document findings so another technician can pick up where you left off.

Air Distribution, Load Calculations, and Safety: Comfort and efficiency hinge on airflow. You will measure static pressure, set blower speeds, and verify filter and coil cleanliness to stay within manufacturers’ recommended pressure drops. The course introduces basic heating and cooling load calculations to size equipment and ducts appropriately, comparing consequences of undersizing (struggling to meet demand) versus oversizing (short cycling and humidity issues). You will practice balancing registers and diagnosing duct leakage with simple pressure tests. Safety is integrated throughout: brazing with proper ventilation and fire watch, handling cylinders, ladder use, and recognizing confined space hazards. A strong emphasis is placed on documentation—airflow readings, amperage, temperature splits—because good data speeds troubleshooting and builds trust with clients.

By the time these three pillars are in place, you will see how they interlock. The refrigeration side tells you what temperatures and pressures should be; electrical confirms the system can achieve those states; airflow ensures heat is actually moved. Treat them like three legs of a sturdy stool: if one is weak, the system wobbles. With disciplined practice, you will move from guessing to diagnosing, and that is the core habit that separates a parts-changer from a professional technician.

Inside the 6 Months HVAC Technician Course: Structure, Labs, and Milestones

Month 1: Safety, Tools, and Fundamentals. You begin with electrical safety, personal protective equipment, and shop protocols. Tool literacy follows—manifold gauges, recovery machines, vacuum pumps, multimeters, torque wrenches, swaging and flaring tools. Classroom sessions introduce heat transfer, pressure-temperature relationships, psychrometrics, and equipment types. Lab time focuses on meter usage, pressure testing with nitrogen, and pulling a proper vacuum on training rigs.

Month 2: Electrical Systems and Controls. Expect daily practice reading schematics and tracing control circuits. You will test motors, measure capacitors, and assemble small relay-based boards that simulate air handlers and condensers. Fault simulations—open windings, weak capacitors, failed contactors—build pattern recognition. You will practice documenting findings in clear, brief notes, a habit that pays off on busy service days.

Month 3: Refrigeration Circuit and Brazing. You will braze joints on copper tubing, purge with inert gas for clean interiors, and pressure test assemblies. Charging methods—weigh-in, superheat, subcooling—are covered alongside recovery and leak-check procedures. You will analyze common field scenarios: low airflow masquerading as low charge, restriction at the metering device, or an overcharged system presenting as high head pressure. The goal is to develop a repeatable process rather than relying on hunches.

Month 4: Air Distribution and Commissioning. Duct design basics, blower settings, static pressure diagnostics, and ventilation standards come into play. You will use anemometers and manometers to measure airflow, then balance a small system to target cfm. Commissioning checklists train you to verify wiring, rotation, charge, airflow, and controls in a logical sequence before calling a system complete.

Month 5: Troubleshooting Deep Dive and Efficiency. Case-based learning ramps up. You will work through no-cool, no-heat, short-cycling, icing, and nuisance trip scenarios. Controls become more sophisticated with sensors and staged equipment. You will quantify improvements from simple fixes—cleaning coils, correcting airflow, replacing a weak capacitor—and see their impact on energy use and comfort.

Month 6: Capstone and Field Experience. A supervised externship or project simulates real service calls. You will handle dispatch notes, document diagnostics, obtain client approvals for repairs, and close out with a clear report. Mock inspections reinforce code awareness and safety. By the end, you will have a small portfolio: photos, readings, and brief write-ups demonstrating your process and results.

Typical time commitments in an accelerated track are roughly 18–25 hours per week, often split between lectures and labs. To make the most of it, plan for additional study time and practice. A short list of skills to reinforce outside class includes: – Interpreting PT charts and plotting system states. – Reading and redrawing a schematic from memory. – Measuring and adjusting static pressure safely. – Recording data neatly so trends are easy to spot. This cadence builds the confident rhythm you will carry onto real rooftops and into mechanical rooms.

Job Opportunities After Completing the Course

With six months of focused training, entry-level roles open across residential, light commercial, and refrigeration settings. Titles vary by employer, but you will commonly see: entry-level service technician, installer helper, maintenance technician, shop technician, and building systems assistant. Each role uses the same fundamentals in different proportions. For example, residential service demands strong customer communication and a broad troubleshooting skill set, while installation teams emphasize rigging, layout, brazing, and commissioning. Light commercial work often involves packaged units and simple controls at larger scales, and refrigeration roles bring product temperature and food safety stakes into sharper focus.

Day-to-day responsibilities typically include preventive maintenance (filters, belts, coil cleaning), electrical testing (voltage, amperage, capacitor health), airflow checks (static pressure, temperature splits), and refrigerant circuit verification (superheat, subcooling). New technicians often start with maintenance routes to build speed and confidence before handling complex diagnostics. As proficiency grows, you can move to commissioning, service calls with intermittent faults, or specialized refrigeration tasks where attention to detail is critical.

Pay and demand reflect the essential nature of the work. In many regions, median annual wages land in the mid–$50,000s, with overtime and shift differentials influencing take-home pay. Experienced technicians, crew leads, and specialists often exceed that figure, particularly in high-demand markets or sectors with 24/7 operations. Industry projections indicate steady employment growth over the coming decade—on the order of single-digit annual percentages—driven by construction, equipment replacements, energy upgrades, and indoor air quality priorities. Seasonality is real, but maintenance contracts, refrigeration, and commercial accounts help smooth the calendar.

Advancement pathways are diverse. Many technicians move into roles such as lead installer, service lead, commissioning technician, building automation specialist, estimator, or project coordinator. Some pursue refrigeration specialization or high-efficiency heat pump expertise to align with electrification trends. Others grow into training, quality assurance, or operations management. A few tips to accelerate your progression: – Keep a clean record of readings for each job; data builds credibility. – Learn one new control sequence each month and practice it on a trainer. – Shadow a senior technician on challenging calls to see how they structure diagnostics. – Stay current on low-GWP refrigerants and safe handling protocols.

Licensing and certification vary by region. Many jurisdictions require a refrigerant handling credential, and some have additional electrical or mechanical licensing. Employers value safety-minded candidates who show up prepared, document clearly, and communicate calmly with clients. If you bring that approach, opportunities tend to multiply—because reliability is rare and appreciated.

Conclusion and Next Steps for Prospective Students

Six months can feel brief, but focused effort turns that window into a meaningful springboard. You will leave with practical skills—safe electrical testing, accurate airflow assessment, and confident handling of the refrigeration circuit—that translate immediately to entry-level roles. The trade offers variety: one day balancing a residential system to tame humidity, the next commissioning a rooftop unit before a busy retail weekend. Over time, your toolkit expands to include deeper controls knowledge, advanced diagnostics, and the judgment that comes only from seeing patterns repeat across many jobs.

Before enrolling, set yourself up for success with a short readiness check. – Time: Can you dedicate 18–25 hours weekly for classes and labs, plus study time? – Math and diagrams: Are you comfortable with fractions, basic algebra, and reading simple schematics? – Physical tasks: Can you work safely on ladders, in mechanical rooms, and on rooftops with appropriate precautions? – Mindset: Do you enjoy methodical problem-solving and documenting measurements? If most answers are yes, you likely have the foundation to thrive in an accelerated track.

As you compare programs, look for evidence of strong lab facilities, thoughtful safety culture, and instructors who emphasize process over shortcuts. Ask how often you will handle real gauges and meters, how troubleshooting is taught, and whether you will complete a capstone or externship. Review sample schedules to confirm there is a clear progression from fundamentals to commissioning. If possible, speak with recent graduates about their first months on the job—what surprised them, and which lessons proved most valuable.

Your path forward is straightforward: choose a solid program, commit to deliberate practice, and document your growth. Keep a small portfolio of lab results, photos of your brazing joints, commissioning checklists, and concise write-ups of diagnostic cases. That portfolio becomes proof of your method and momentum. Enter the trade with humility and curiosity, and you will find steady work, respected skills, and room to grow. The systems you install and maintain will quietly support comfort, health, and productivity—making your craft both practical and meaningful.